Products for office automation equipment

-

-

Our extensive portfolio complies with the entire scope of office automation equipment, and our unique core technologies materialize innovative portfolio and attentive services.

The traceability system has been established with in-house design and in-house compositions, thus contributing to high quality assurance.

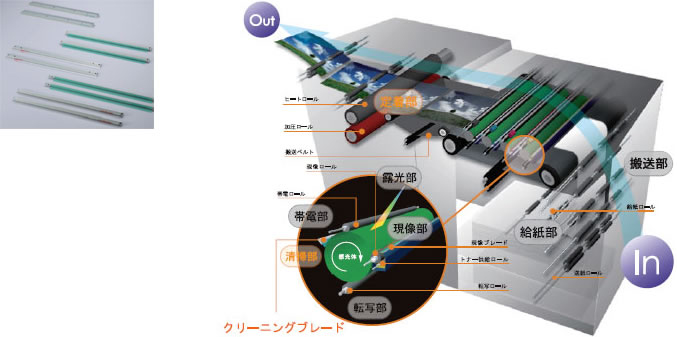

The peripheral unit of the photoreceptor (image-forming parts) is equipped with developing and charging rollers and a cleaning blade, and the fixation unit consists of fixing and pressurizing rollers and a fixation belt.

For more information of the product, click the link below.

- Basic Information

- Documents and Catalogs

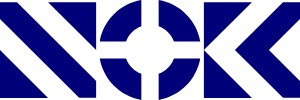

Basic Construction

Developing and charging rollers

The developing roller feeds a specified quantity of toner to the photoreceptor, and the charging roller applies a specified quantity of charges to the photoreceptor. Our products feature good control of conductivity at high precision.

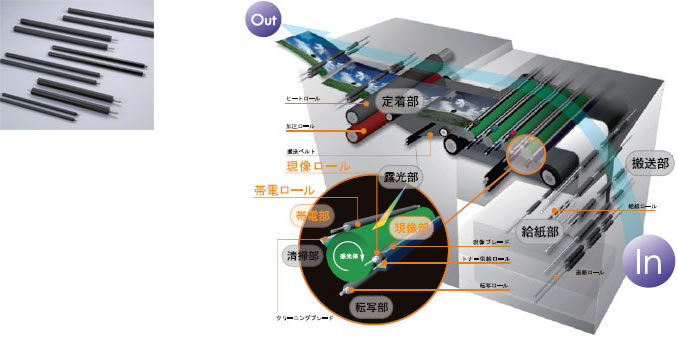

Pressurizing and heat rollers and fixation belt

The pressurizing roller applies uniform pressure while toner is fixed. It is made from a less-resilient flexible material with low heat capacity to reduce the warm-up time and ensure adequate nip width.

The fixation belt is a metal-rubber composite belt featuring superior thermal conductivity and pyrogenicity. It can control thickness at high precision and form a uniform surface.

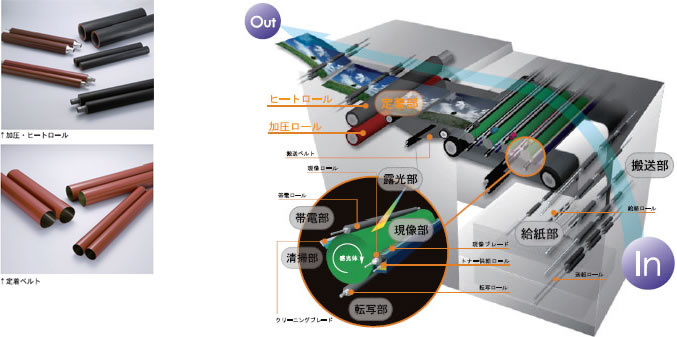

Feed rollers

The feed roller properly feeds each sheet of paper. Products can be fabricated with highly-durable materials with stable coefficient of friction.

Cleaning blade

The cleaning blade removes residual toner or foreign matters from the surface of photoreceptor, rollers, or belts. It is made from high-precision materials with superior abrasion resistance.

* We do not guarantee the integrity of data other than those provided by us.