e-Mobility Industrial Equipment

The spread of next-generation vehicles is progressing toward the realization of a low-carbon society.

NOK offers various products such as low friction seals that reduce driving-power losses and contribute to low fuel and power consumption, seals and greases that contribute to quietness, corrosion measures, and thermal management required of electric vehicles (e-Mobility). We have been developing new products and technologies, aiming to contribute to a safe and comfortable mobility society of the future.

Heat Countermeasures

Thermally conductive compound like clay 【Under development】

-

-

Newly developed solution for heat dissipation concerns

This is a clay-like heat dissipation component that is ideal for the thermal management of devices. It has a high degree of deformation freedom and follows the complex gaps between the heating element and the heat sink to achieve efficient heat dissipation. Compared to the silicone grade currently for sale, it does not contain siloxane and is superior in oil resistance. Moreover, compared with the heat dissipation sheet, it is easier to reapply, and less likely to cause leakage as heat dissipation grease does. The texture is soft and not sticky.

-

This is a clay-like heat dissipation component that is ideal for the thermal management of devices. It has a high degree of deformation freedom and follows the complex gaps between the heating element and the heat sink to achieve efficient heat dissipation. Compared to the silicone grade currently for sale, it does not contain siloxane and is superior in oil resistance. Moreover, compared with the heat dissipation sheet, it is easier to reapply, and less likely to cause leakage as heat dissipation grease does. The texture is soft and not sticky.

Heat Countermeasures

Thermally conductive rubber

-

-

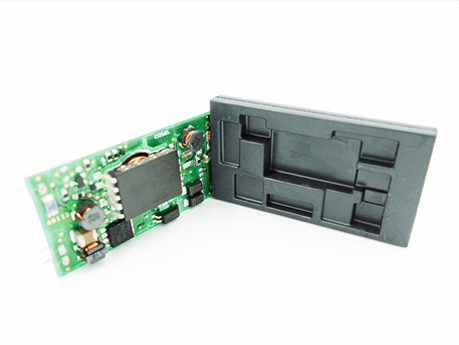

Higher thermal conductivity mold rubber

Thermally conductive rubber can be molded into a three-dimensional shape along the heating element. While having the elasticity peculiar to rubber, following the shape of the heating element increases the contact area and provides a higher heat dissipation effect compared to sheet-shaped heat conductive rubber. Since it has electrical insulation and low outgassing characteristics, it can be used in automobile units such as ECUs, inverters, and PCUs, as well as in the vicinity of electronic components.

-

Thermally conductive rubber can be molded into a three-dimensional shape along the heating element. While having the elasticity peculiar to rubber, following the shape of the heating element increases the contact area and provides a higher heat dissipation effect compared to sheet-shaped heat conductive rubber. Since it has electrical insulation and low outgassing characteristics, it can be used in automobile units such as ECUs, inverters, and PCUs, as well as in the vicinity of electronic components.

Heat Countermeasures

Integrated thermally conductive materials 【Under development】

-

-

Composite product of conductive rubber and compound like clay

It is easy to handle because it is a product in which a clay-like thermally conductive material is covered with a thermally conductive rubber product. Since the contact with the heating element is a soft clay-like material, it has excellent adhesion to complex and uneven spaces. It has electrical insulation and can be used around electronic components.

-

It is easy to handle because it is a product in which a clay-like thermally conductive material is covered with a thermally conductive rubber product. Since the contact with the heating element is a soft clay-like material, it has excellent adhesion to complex and uneven spaces. It has electrical insulation and can be used around electronic components.

Heat Countermeasures

Flame retardant rubber 【Under development】

-

-

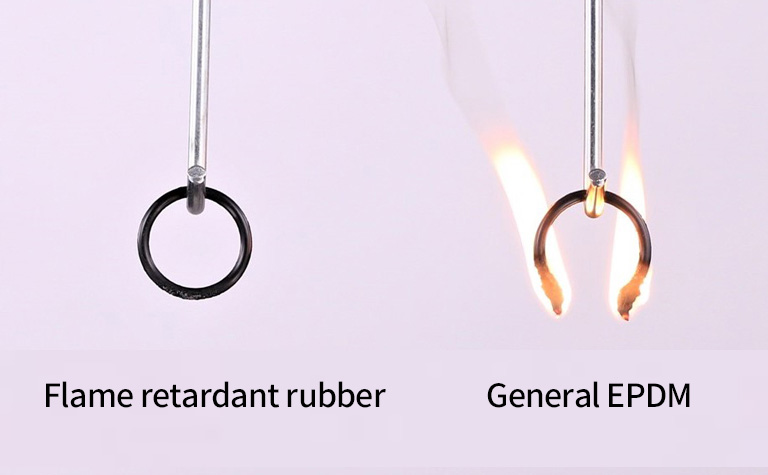

High flame-retardant EPDM material for sealing battery case and its surrounding parts used for electric vehicles

We developed the EPDM which has high flame-retardant properties and it is equivalent to the UL94V-0 standard applied in the international market. Considering international environmental concerns, it is halogen-free material with excellent durability and low temperature properties. It is expected to apply to O-rings and gaskets used for the electric vehicle battery case and its surrounding parts.

-

We developed the EPDM which has high flame-retardant properties and it is equivalent to the UL94V-0 standard applied in the international market. Considering international environmental concerns, it is halogen-free material with excellent durability and low temperature properties. It is expected to apply to O-rings and gaskets used for the electric vehicle battery case and its surrounding parts.

Ecomaterial

Biomass material

-

-

EPDM with 30% biomass content

Toward carbon neutrality, this EPDM material achieved 30% biomass content (organic material ratio). It has the same physical properties as general-purpose and water-use O-ring materials, and can reduce polymer CO₂ emissions by 40%.

-

Toward carbon neutrality, this EPDM material achieved 30% biomass content (organic material ratio). It has the same physical properties as general-purpose and water-use O-ring materials, and can reduce polymer CO₂ emissions by 40%.

Anti-corrosion Measures

Anti-corrosive seal & grease for aluminum parts

-

-

Delay the speed of corrosion and contribute to the improvement in sealability of aluminum parts

We developed anti-corrosive gaskets and grease for aluminum parts of electrified vehicles. The original cross-section design of gaskets delays the speed of corrosion while maintaining high sealing performance, thus extending unit life. The combined use of those gaskets and the water-resistant grease increases the corrosion resistance even more. It reduces cost and man-hours.

-

We developed anti-corrosive gaskets and grease for aluminum parts of electrified vehicles. The original cross-section design of gaskets delays the speed of corrosion while maintaining high sealing performance, thus extending unit life. The combined use of those gaskets and the water-resistant grease increases the corrosion resistance even more. It reduces cost and man-hours.

Electromagnetic Wave

Conductive ring 【Under development】

-

-

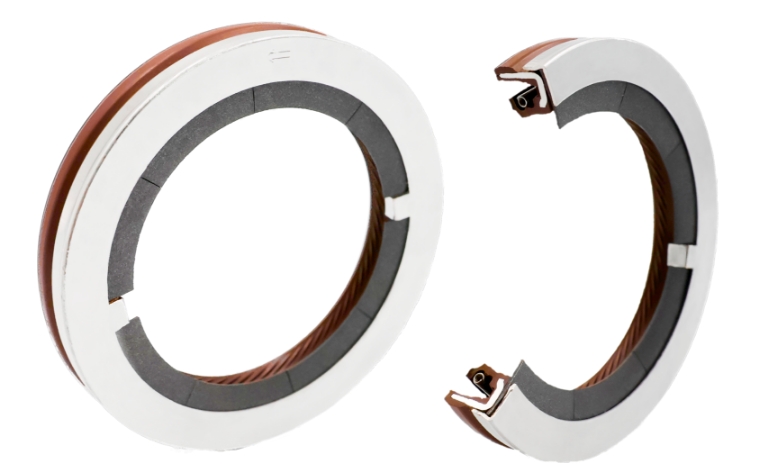

Reducing electromagnetic wave noise and electrolytic corrosion of motors

This oil seal ring diverts electric current from a motor shaft to a housing while maintaining the sealing performance. It solves problems such as radio noise caused by induced current from motors and electrolytic corrosion of bearing races. Its simple structure with conductive rubber, grease, non-woven, and PTFE reduce cost and space, compared to conventional items such as grounding brushes and wires.

-

This oil seal ring diverts electric current from a motor shaft to a housing while maintaining the sealing performance. It solves problems such as radio noise caused by induced current from motors and electrolytic corrosion of bearing races. Its simple structure with conductive rubber, grease, non-woven, and PTFE reduce cost and space, compared to conventional items such as grounding brushes and wires.

Low Fuel & Power Consumption

Oil seal for high-speed rotation motor shaft

-

-

Supporting high speed, forward and reverse rotation of motors

This oil seal is composed of fluoro rubber with excellent heat resistance. The optimal helix shape designed for forward and reverse rotation of motors improves sealing performance during reverse rotation. Our seal coating technology helps to reduce friction and sliding heat generation. We offer the optimized seal design and specifications for low fuel and energy consumption.

-

This oil seal is composed of fluoro rubber with excellent heat resistance. The optimal helix shape designed for forward and reverse rotation of motors improves sealing performance during reverse rotation. Our seal coating technology helps to reduce friction and sliding heat generation. We offer the optimized seal design and specifications for low fuel and energy consumption.

Low Fuel & Power Consumption

Low friction technology

-

-

Contributing to low fuel and power consumption with low friction technology

The high-performance seal brand that contributes to fuel and power consumption is developed by using four low friction technologies; design, material, surface, and grease technologies. The product line includes Oil seals, Seal rings (TS-Rings), O-ring with SP coating, Rod seals for rotation and oscillation, and Oval-rings with CNT.

-

The high-performance seal brand that contributes to fuel and power consumption is developed by using four low friction technologies; design, material, surface, and grease technologies. The product line includes Oil seals, Seal rings (TS-Rings), O-ring with SP coating, Rod seals for rotation and oscillation, and Oval-rings with CNT.

Low Fuel & Power Consumption

Surface textured mechanical seal for E-motor cooling system

-

-

Supporting faster rotational speed and higher efficiency of electric motor

Surface textured mechanical seal is developed for the shaft cooling system of an electric traction motor, E-Axle, and reduction gear of EV. The surface texturing applied on the sliding surface of this seal brings two contraries together: extremely low torque (90+% reduction) with high sealing performance, coupled with high-speed capability. Surface textured mechanical seal supports higher rotational speed and higher efficiency of the traction motor.

-

Surface textured mechanical seal is developed for the shaft cooling system of an electric traction motor, E-Axle, and reduction gear of EV. The surface texturing applied on the sliding surface of this seal brings two contraries together: extremely low torque (90+% reduction) with high sealing performance, coupled with high-speed capability. Surface textured mechanical seal supports higher rotational speed and higher efficiency of the traction motor.

Low Fuel & Power Consumption

Crescent shape seal ring

-

-

Improving the starting performance of automatic engine start/stop system

This seal ring is the world's first seal ring with an asymmetrical shape (crescent shape) that improves its followability to the housing. This feature reduces 80% of the leak rate of the hydraulic pump at no pressure compared to the conventional product. It can achieve downsizing and improve the fuel efficiency of a hydraulic pump.

-

This seal ring is the world's first seal ring with an asymmetrical shape (crescent shape) that improves its followability to the housing. This feature reduces 80% of the leak rate of the hydraulic pump at no pressure compared to the conventional product. It can achieve downsizing and improve the fuel efficiency of a hydraulic pump.

Low Fuel & Power Consumption

PTFE gas seal (high temperature & pressure seal)

-

-

Reducing the number of surrounding parts while maintaining sealing performance under harsh environments

The developed PTFE seal with metal spring has improved heat resistance, poor lubrication resistance, pressure resistance, and eccentric followability compared to conventional rubber seals. It can be used as a gas seal for rotation and reciprocation under high temperature, high pressure, and poor lubrication caused by exhaust gas from EGR and turbo, etc.

-

The developed PTFE seal with metal spring has improved heat resistance, poor lubrication resistance, pressure resistance, and eccentric followability compared to conventional rubber seals. It can be used as a gas seal for rotation and reciprocation under high temperature, high pressure, and poor lubrication caused by exhaust gas from EGR and turbo, etc.

CASE

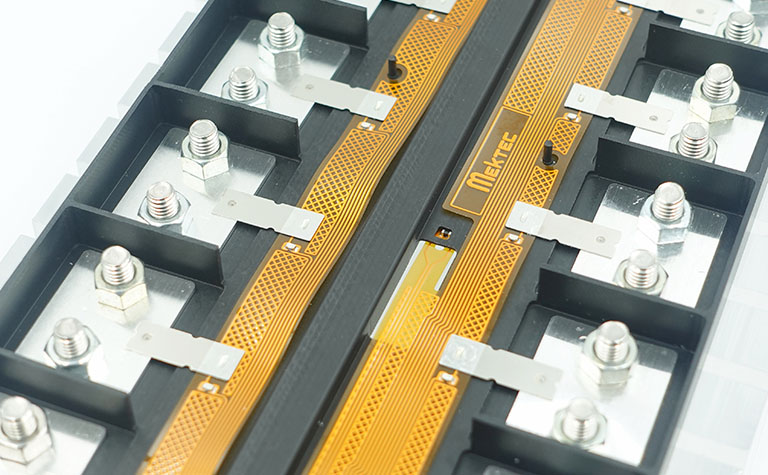

FPC (Flexible Printed Circuits) for Automotive

-

-

Contributing to miniaturization and space saving of electronic equipment

Flexible Printed Circuits (FPC) are thin and flexible circuit board, which is essential for internal wiring where miniaturization and high-density mounting are required. We have been responding to various customer needs for FPC applications in the automotive industry. As a global brand, “MEKTEC,” we supply FPCs to customers around the world.

-

Flexible Printed Circuits (FPC) are thin and flexible circuit board, which is essential for internal wiring where miniaturization and high-density mounting are required. We have been responding to various customer needs for FPC applications in the automotive industry. As a global brand, “MEKTEC,” we supply FPCs to customers around the world.

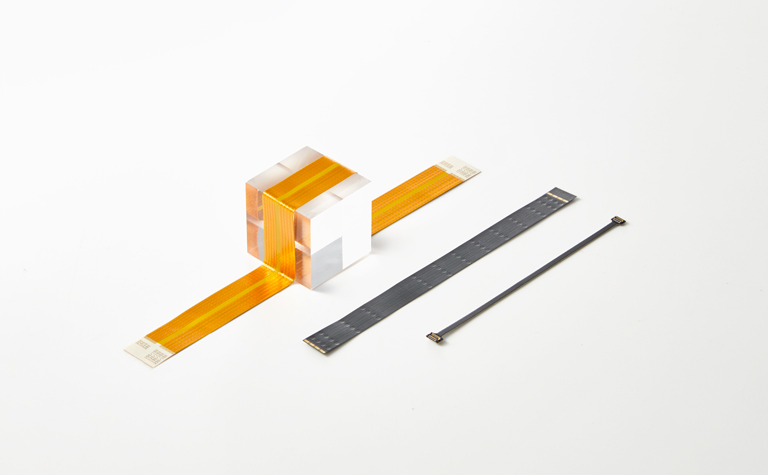

CASE

FPC for high-speed transmission

-

-

FPC for 5G terminals contributed to the expansion of battery capacity

This FPC is designed to improve data transmission speed in IoT society. It is thinner and more flexible than coaxial cables, which enables making space-saving possible. Modified Polyimide (MPI) material is used to improve transmission speed, flexural strength, and heat resistance. It helps to maximize the size of the battery in smartphone and provide fully shielded high-speed transmission in automotive applications.

-

This FPC is designed to improve data transmission speed in IoT society. It is thinner and more flexible than coaxial cables, which enables making space-saving possible. Modified Polyimide (MPI) material is used to improve transmission speed, flexural strength, and heat resistance. It helps to maximize the size of the battery in smartphone and provide fully shielded high-speed transmission in automotive applications.

CASE

High heat & high current resistant FPC 【Under development】

-

-

Contributing to the miniaturization and higher speed of SiC power modules & supporting next-generation power modules

This FPC can replace the interconnection of solder and aluminum wire bonding used for power devices, which enables the downsizing of the devices. It promisingly satisfies the needs of the automotive power control unit and powertrain by reducing parasitic inductance and improving heat resistance over 200℃.

-

This FPC can replace the interconnection of solder and aluminum wire bonding used for power devices, which enables the downsizing of the devices. It promisingly satisfies the needs of the automotive power control unit and powertrain by reducing parasitic inductance and improving heat resistance over 200℃.

CASE

Rubber applicable to near-infrared sensor 【Under development】

-

-

Rubber that looks black and becomes transparent in near-infrared light

Rubber containing ordinary carbon does not transmit infrared light, but by improving the mixing of rubber compounds, we have developed the rubber that becomes transparent in near-infrared area while still maintaining the appearance of ordinary rubber. It is more flexible and stretchable than plastic filters, and we expect to see applications for driver monitoring and other monitoring services which require infrared light.

-

Rubber containing ordinary carbon does not transmit infrared light, but by improving the mixing of rubber compounds, we have developed the rubber that becomes transparent in near-infrared area while still maintaining the appearance of ordinary rubber. It is more flexible and stretchable than plastic filters, and we expect to see applications for driver monitoring and other monitoring services which require infrared light.

CASE

Rubber electrode for biomedical signals

-

-

Provides comfortable biological sensing

Flexible rubber coated fabric electrode that can be used repeatedly in dry conditions. It can be used not only for detection of biomedical signals but also for electrical stimulation applications. Since it can be cut, sewn or glued, it can be easily attached to wearable devices.In automobiles, including wearable devices, it is expected to be applied to steering as driver monitoring.

-

Flexible rubber coated fabric electrode that can be used repeatedly in dry conditions. It can be used not only for detection of biomedical signals but also for electrical stimulation applications.Since it can be cut, sewn or glued, it can be easily attached to wearable devices.In automobiles, including wearable devices, it is expected to be applied to steering as driver monitoring.

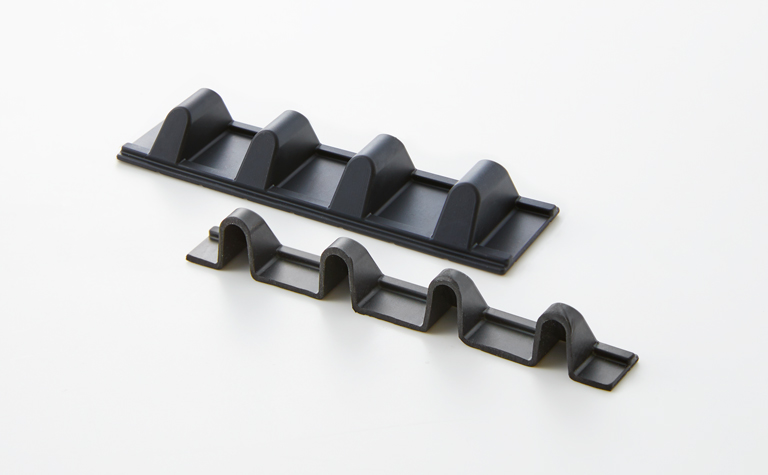

NVH

Cushion rubber

-

-

Cushion rubber that fills the gap and prevents rattling with soft repulsive force

Cushion rubber is a convex part with a hollow film shape. It enables appropriate load control for the low-intensity components even under large compression. The material doesn't affect the electronic components. Therefore, it is useful for filling the gaps, pressing parts, and preventing a backlash around the battery or other electric units.

-

Cushion rubber is a convex part with a hollow film shape. It enables appropriate load control for the low-intensity components even under large compression. The material doesn't affect the electronic components. Therefore, it is useful for filling the gaps, pressing parts, and preventing a backlash around the battery or other electric units.

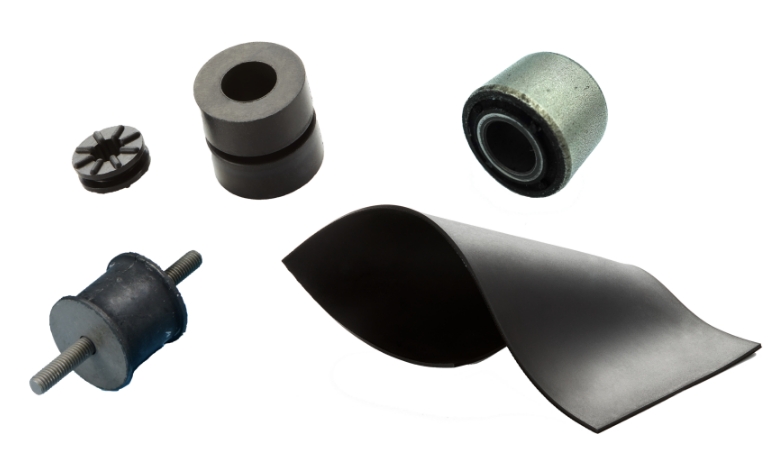

NVH

Anti-vibration & noise reduction technology

-

-

Creation of further quieter spaces required for electric vehicles

NOK provides NVH solutions based on our technical experiences and contributes to the quiet space required for electric vehicles. We design and develop high-performance rubber such as high damping rubber, the anti-vibration and noise reduction products, for mounts and dampers. We can also provide proposals for suitable installation positions based on our depth knowledge of NVH including our noise evaluation analysis.

-

NOK provides NVH solutions based on our technical experiences and contributes to the quiet space required for electric vehicles. We design and develop high-performance rubber such as “High Damping Rubber (HDR)”, the anti-vibration and noise reduction products, for mounts and dampers. We can also provide proposals for suitable installation positions based on our depth knowledge of NVH including our noise evaluation analysis.

Safety & Comfort

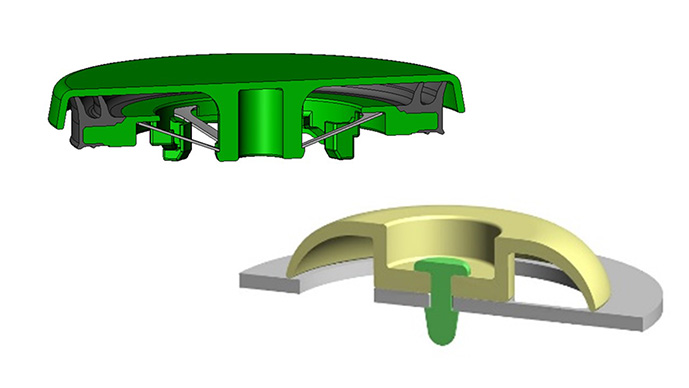

Pressure control valve 【Under development】

-

-

Prevention of pressure accumulation inside the case

The large flow type has a structure in which the umbrella-shaped valve is held by a leaf spring, and when the internal pressure rises, the umbrella rises to release the pressure inside the battery pack. It is possible to tune according to layout conditions, valve opening pressure and flow rate.

If you require a simpler mechanism, we can also propose a small/medium flow rate type or a pressure control valve that is a rubber umbrella valve.

When the internal pressure rises, the head part floats and opens the valve to release the pressure.

By adjusting the tightening margin, etc., it is possible to consider adjusting the valve opening pressure and flow rate according to the required characteristics. -

The large flow type has a structure in which the umbrella-shaped valve is held by a leaf spring, and when the internal pressure rises, the umbrella rises to release the pressure inside the battery pack. It is possible to tune according to layout conditions, valve opening pressure and flow rate.

If you require a simpler mechanism, we can also propose a small/medium flow rate type or a pressure control valve that is a rubber umbrella valve.

When the internal pressure rises, the head part floats and opens the valve to release the pressure.

By adjusting the tightening margin, etc., it is possible to consider adjusting the valve opening pressure and flow rate according to the required characteristics.

Improved Workability

Foldable rubber gasket 【Under development】

-

-

Foldable gasket for compact storage and large enclosures

By making the gasket foldable, NOK improved the assemblability, handling, transportation and storage of gaskets for large enclosures such as battery cases. Since the gasket can stand on its own, it provides a sealing function even without grooves in low-pressure applications.

-

By making the gasket foldable, NOK improved the assemblability, handling, transportation and storage of gaskets for large enclosures such as battery cases. Since the gasket can stand on its own, it provides a sealing function even without grooves in low-pressure applications.

Space & Weight Saving

Space-saving gasket

-

-

Contributing to unit downsizing and weight reduction with sealing technology

This newly designed space-saving gasket reduces the unit volume while maintaining stable sealing performance even under high pressure. It can reduce sealing space compared to conventional gaskets and O-rings, and has excellent durability. In addition, since the inner wall of the seal assembly groove is not required, it contributes to the reduction of grooving man-hours. It is applicable for a wide range of sealing applications such as water and gas, including in-vehicle units.

-

This newly designed space-saving gasket reduces the unit volume while maintaining stable sealing performance even under high pressure. It can reduce sealing space compared to conventional gaskets and O-rings, and has excellent durability. In addition, since the inner wall of the seal assembly groove is not required, it contributes to the reduction of grooving man-hours. It is applicable for a wide range of sealing applications such as water and gas, including in-vehicle units.

PRODUCTS

For more details, please visit our products page.