Hollow fiber membranes for MBR

-

-

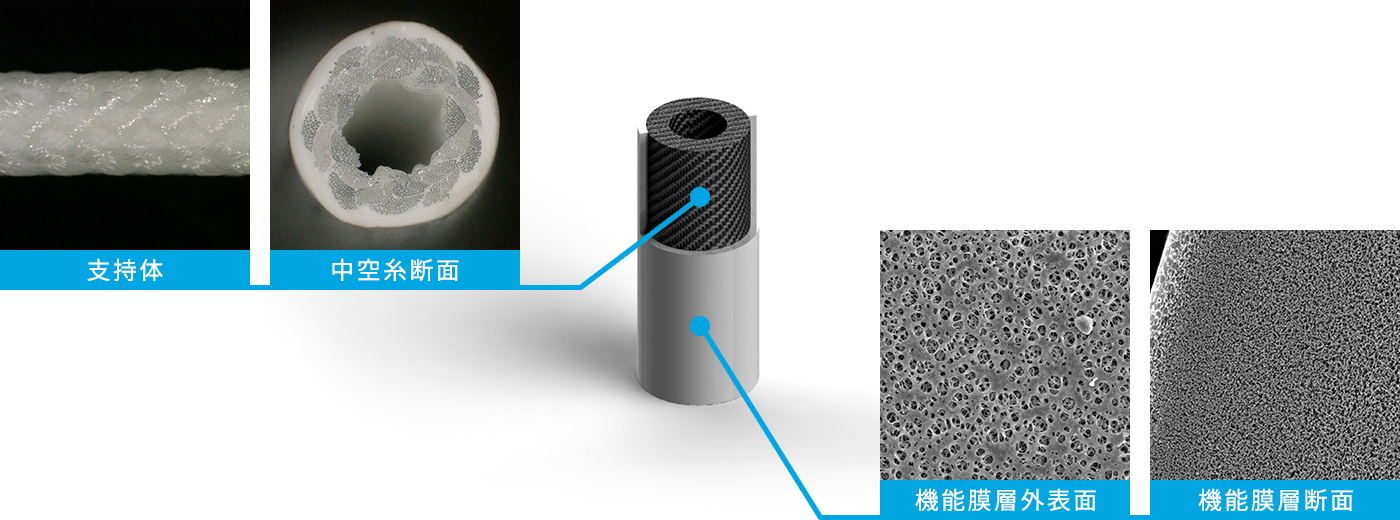

NOK’s hollow fiber membranes for MBR are physically reinforced with a support, and PVDF membranes are employed as functional membranes, thus attaining superior chemical resistance, scratch resistance, permeability, and antifouling property. Compact MBR systems with high performance can be constructed for various water qualities at low cost.

- Basic Information

- Documents and Catalogs

SEM image

NOK’s hollow fiber membranes for MBR are physically reinforced with a support, and PVDF membranes are employed as functional membranes, thus attaining superior chemical resistance, scratch resistance, permeability, and antifouling property. Compact MBR systems with high performance can be constructed for various water qualities at low cost.

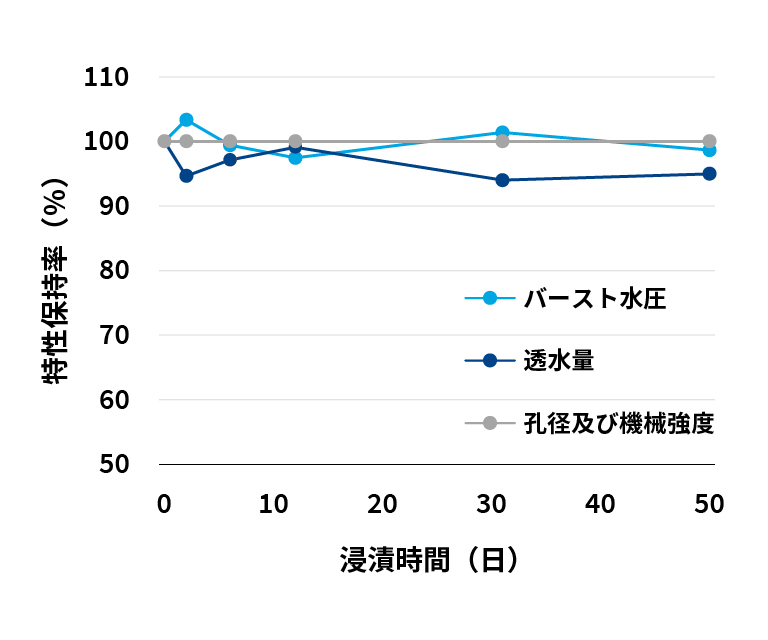

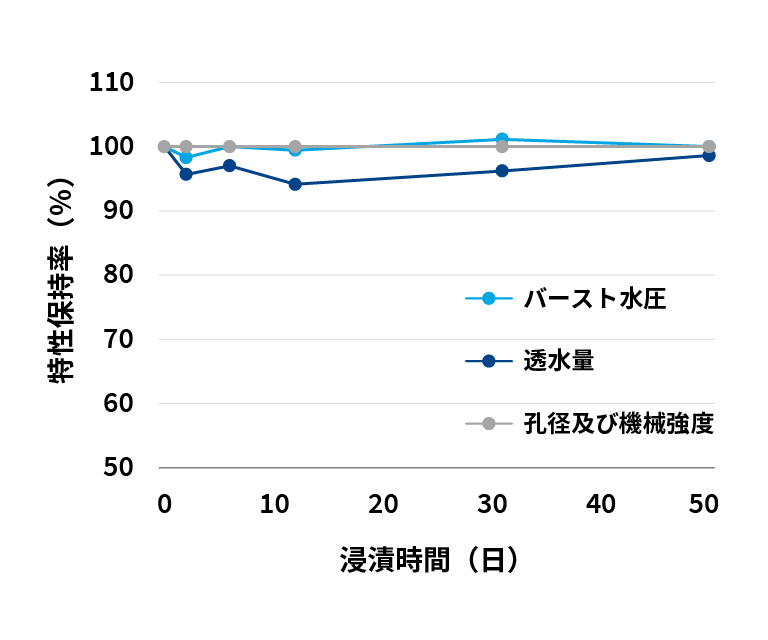

Chemical resistance of hollow fiber membranes for MBR

-

Conditions of chemical immersion test

Concentration of immersion chemical Citric acid: 50,000 ppm Sodium hypochlorite: 3,000 ppm Immersion temperature 25℃ (ambient temperature) Immersion duration 1,200 hours

(equivalent to 10 years: Chemical cleaning for 2 h/week)

-

Citric acid immersion test result

-

Sodium hypochlorite immersion test result

-

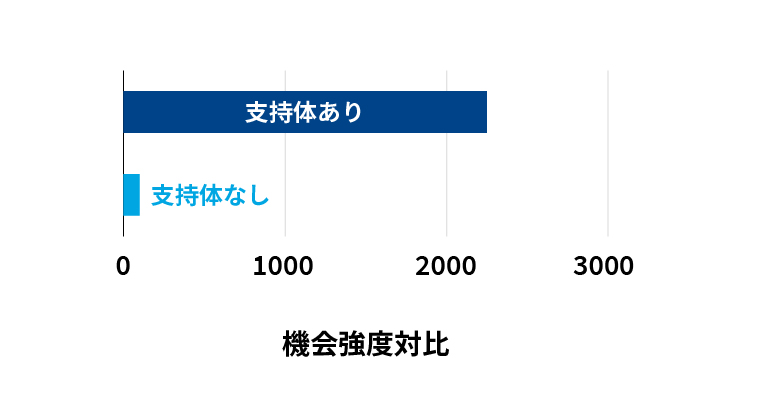

Mechanical strength properties

The mechanical strength of MBR PVDF membranes of NOK reinforced with a support is 20 times more of a membrane without a support set as 100.

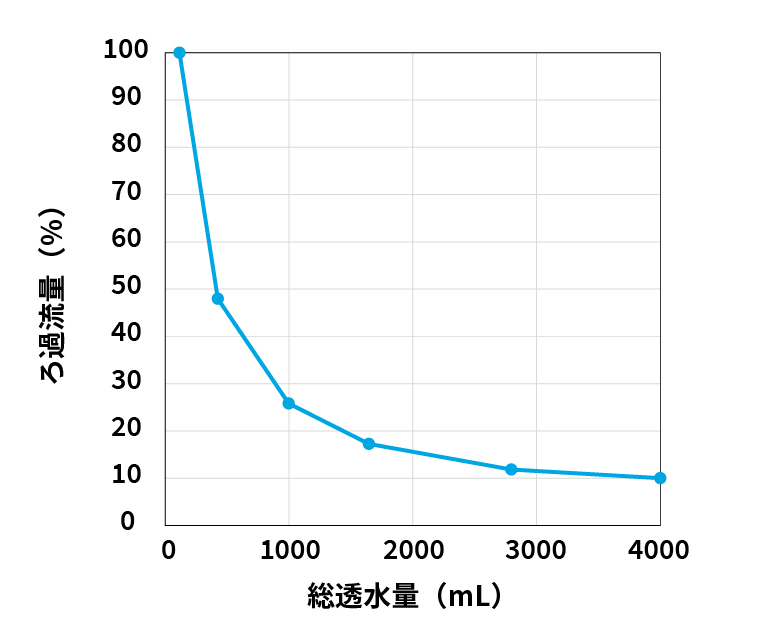

Clog property

-

Clog test conditions

Effective length of membrane 1500mm Filter system Suction from the inner side of the membrane Suction pressure -60kPa Substance to be filtered Raw water sludge MLSS: 200 ppm -