Products for use in office automation equipment

NOK Group has been contributing to technological innovation of office automation equipment through its expertise in material development, ability to plan and design unique products, and production technologies.

Rollers are widely used around photoreceptors that determine the performance of copiers and for fixing parts that require high functionality and durability.

Development rollers and charge rollers

-

-

These products are used around photoreceptors, and their electric conductivity is controlled with high precision. Development rollers are made of urethane or silicone to apply a specific amount of electric charge to the toner and transport it to the photoreceptor. Charge rollers are used to apply a certain amount of electric charge to the photoreceptor.

Major applications

Surrounding areas of office machinery photoreceptors

-

Major applications

Surrounding areas of office machinery photoreceptors

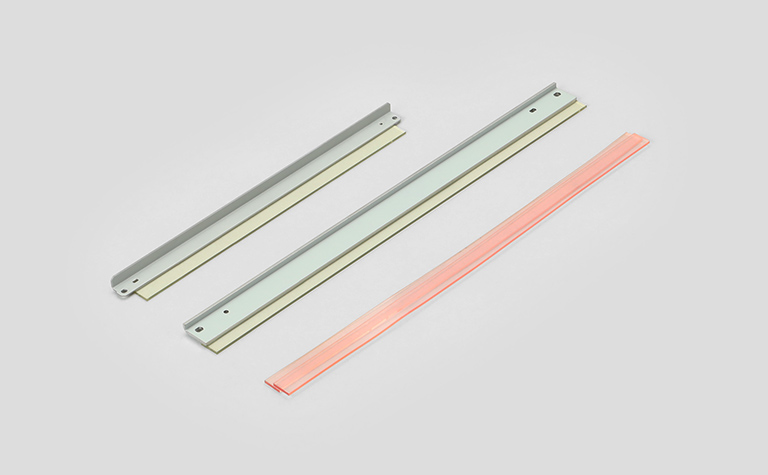

Cleaning blade

-

-

These products are used to remove toner residue and other foreign particles that adhere to the surface of photoreceptors, rollers and belts. They are highly abrasion-resistant, tolerant to temperature changes, and provide stable cleaning performance during environmental changes.

Major applications

Surrounding areas of office machinery photoreceptors

-

Major applications

Surrounding areas of office machinery photoreceptors

Fixing belts and pressure rollers

-

-

These products are used for fixing parts. Fixing belts are made by combining metal and rubber, and fix the toner to the paper using heat and pressure. They require shorter warm-up time compared to fixing rollers, and are superior in terms of printing quality, speed and energy efficiency. Pressure rollers are used to fix heated toner to paper by applying pressure evenly. Stable fixing outcomes last a long time.

Major applications

Fixing parts of office machinery

-

Major applications

Fixing parts of office machinery

For more details, please visit the SZT website.