News/ Events ニュース・展示会情報

Application Guide 製品情報

-

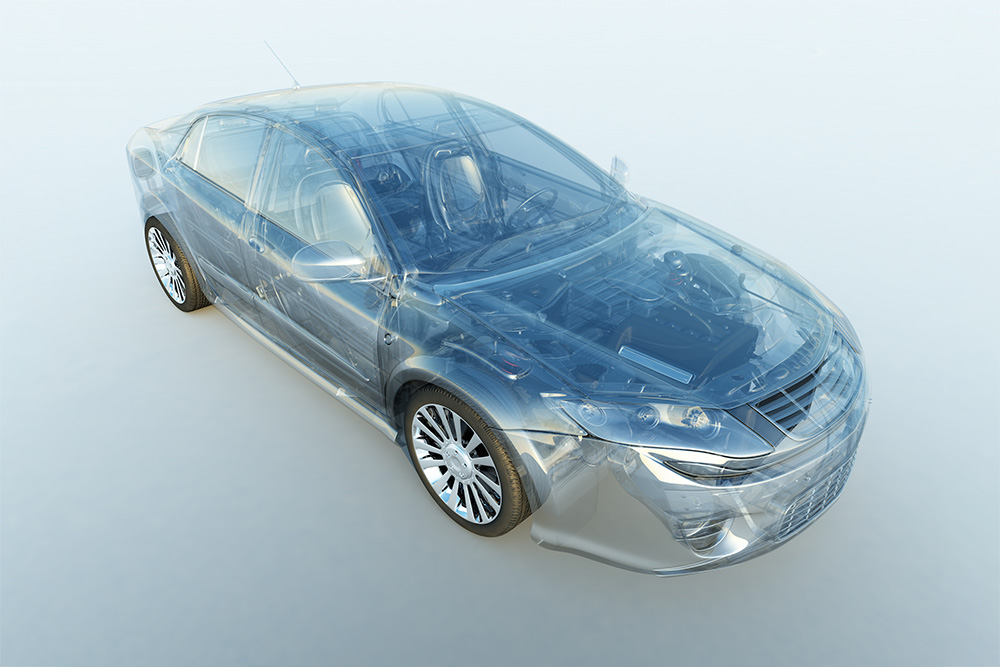

自動車に使われる製品

自動車には多くのNOKグループ製品が採用されており、高機能かつ環境に配慮した製品で、皆さまの安全で快適な暮らしを支えています。

-

電動車に使われる製品

安全で快適な未来のモビリティ社会を支えるべく、低炭素社会の実現に向けた新製品・新技術の開発に取り組んでいます。

-

水素関連機器に使われる製品

カーボンニュートラルの達成に向けて、水素やアンモニアの利活用が期待されています。NOKグループでは水素社会の実現に貢献できるよう、「つくる」「ためる」「はこぶ」「つかう」それぞれの分野で活躍する新製品・新技術の開発に取り組んでいます。

-

一般産業機器に使われる製品

NOKのコア技術から生み出される数多くの製品は、建設機械や農業機械、住宅設備機器や各種プラント、ロボットなど、さまざまな領域で活躍しています。

-

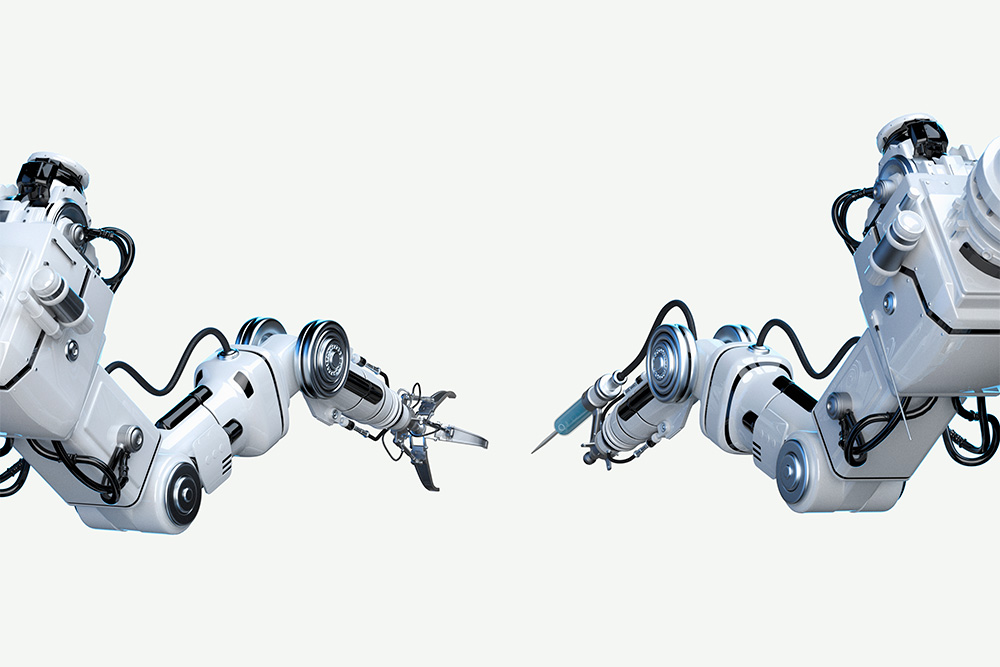

ロボットに使われる製品

自動化や省人化のニーズが高まり、ロボットの需要が拡大しています。NOKグループが有するシール製品および潤滑製品の豊富なラインアップの中から、耐久性・組み立て性・メンテナンス性に優れた製品をご提案することで、人とロボットが共生する社会に貢献します。

-

食品機械に使われる製品

NOKグループでは食品衛生法・水道法適合材の豊富なラインナップや、食品機械用潤滑剤など、家庭用から業務用まで、信頼性が求められる幅広い用途で多数の採用実績があります。

-

情報電子機器に使われる製品

今や生活に欠かせないスマートフォンから、タブレット端末、ウェアラブル機器、さらには次世代自動車まで、さまざまな電子機器の中で皆さまの便利な暮らしを支えています。

-

OA機器に使われる製品

複写機の性能を左右する感光体周辺部や、高機能・高耐久性が求められる定着部には、多くのロール製品が使われています。

Special スペシャルコンテンツ

Recruit Information 採用情報

-

よりよい製品をつくることで、より豊かな社会へと貢献していきたい。NOKグループは各社とも同じ夢に向かって事業を展開しています。

あなたも、その夢を共有してみませんか? -

NOK Group

-

- イーグル工業株式会社

- 日本メクトロン株式会社

- シンジーテック株式会社

- NOKクリューバー株式会社

- ユニマテック株式会社

- 株式会社エストー

-

- Freudenberg-NOK General Partnership

- Thai NOK Co., Ltd.

- PT. NOK Indonesia

- Vietnam NOK Co., Ltd.

- Wuxi NOK-Freudenberg Oilseal Co., Ltd.

- Changchun NOK-Freudenberg Oil seal Co., Ltd.

-

- NOK-Freudenberg Group Sales (China) Co., Ltd.

- NOK-Freudenberg Group Trading (China) Co., Ltd.

- Freudenberg NOK Pvt., Ltd.

- Pyung Hwa Oil Seal Industry Co., Ltd.

- NOK Europa GmbH